Key Takeaways

- Managing material supply is vital for timely production and quality assurance in electronics manufacturing.

- Delays in material delivery can disrupt operations and increase costs; robust supply chain planning can help mitigate these issues.

- NOTE focuses on precision in material supply, working closely with suppliers to ensure availability and quality throughout the process.

- Key strategies include optimising inventory control, collaborating with suppliers, mitigating risks, and enforcing quality assurance standards.

- NOTE’s commitment to strategic sourcing and supplier oversight helps maintain continuity and support efficient production.

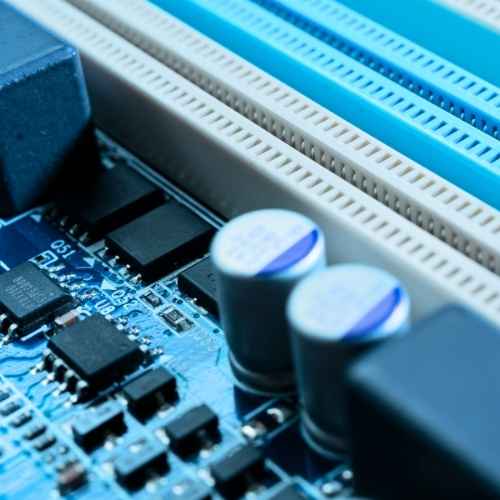

Managing material supply is critical to keeping production on schedule and maintaining consistent quality. At NOTE, we take a proactive approach to ensure every component arrives on time and meets stringent standards.

Why Material Supply Matters

In electronics manufacturing, delays in material delivery can halt production and increase costs. By implementing robust supply chain planning and inventory control, businesses can avoid bottlenecks and maintain operational efficiency. According to Supply Chain Digital, effective material management “reduces lead times and improves production flow,” making it a cornerstone of manufacturing success. [gep.com]

Ensuring Timely Deliveries and Quality

Our material supply process focuses on precision and predictability. We work closely with trusted suppliers to guarantee availability and monitor quality at every stage. As IndustryWeek highlights, strong supplier relationships and real-time visibility are key to “minimising disruptions and ensuring consistent quality”. [tradebeyond.com]

How NOTE Delivers Confidence

- Inventory Control: Advanced planning tools keep stock levels optimised.

- Supplier Collaboration: Close partnerships ensure reliability and compliance.

- Risk Mitigation: Diversified sourcing reduces vulnerability to shortages.

- Quality Assurance: Rigorous checks maintain standards across all materials.

Our Commitment to Your Schedule

At NOTE, we understand that timely material supply is the backbone of efficient production. By combining strategic sourcing, inventory management, and supplier oversight, we help customers maintain continuity and deliver products without compromise.